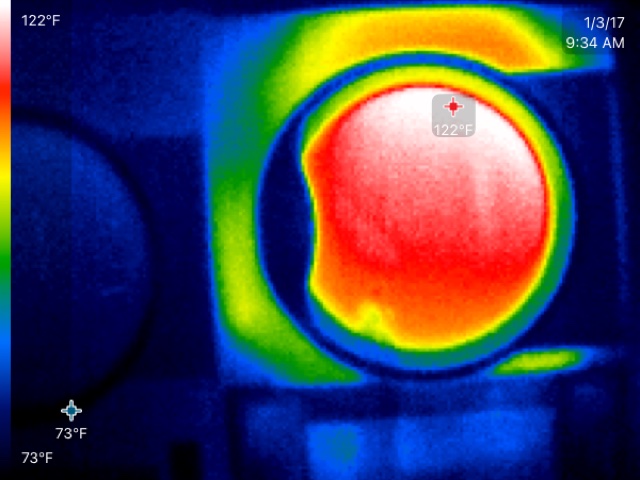

How To Clean A RINNAI On Demand Tankless Water Heater

As I mentioned in a previous post, Water Heaters- Tank or Tankless, the flow is reduced on a Tankless water heater to maintain the output temperature. So if the heat transfer efficiency is reduced it will take longer the fill your machines and increase the cycle time of the washer.