County Property Taxes

Don’t forget about them Many years ago when I was first getting into the Industry I got a little aggressive and missed a few things. After construction of my first store and opening in July of 2010 I looked at…

Don’t forget about them Many years ago when I was first getting into the Industry I got a little aggressive and missed a few things. After construction of my first store and opening in July of 2010 I looked at…

Don’t have too many, people don’t read them anyway I have needed to upgrade my store signs for awhile to reflect some new procedures for refunds. Previously I would have people just write the information on a slip of paper…

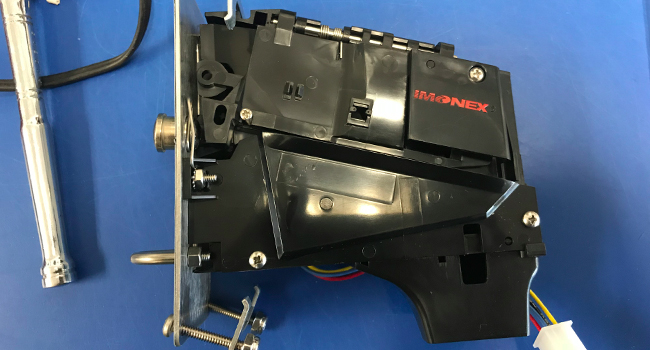

Speed Queen Washer Shock Absorber Change Over time the shock absorbers in the Speed Queen / IPSO soft mount washers will wear out. At this point, they become just a set of springs. …